If you deal with manufacturing or shipping operations, you must know the importance of timely packaging and role of strapping equipment in it. From securing pallets to bundling goods, the right strapping tool can make all the difference.

But how to choose a strapping machine that suits your business needs?

All Pack Tech is here to guide you in buying strapping equipment. We will explain the different types of strapping machines, their uses, and factors to consider while buying. So, you can avoid delays in supply, product damage, or extra expenses.

At All Pack Tech, we focus on providing efficient and high-quality packaging equipment in Australia. So, your supply chain runs smoothly with minimal downtime.

Before buying strapping equipment, let’s find out the basic details you should know to choose the best option.

What is Strapping Equipment? What You Should Know Before Buying It?

Strapping equipment refers to the machinery used to bind the products or bundles together. They are also called banding tools. They secure the goods by wrapping and fastening a durable packing material around them.

These machines come in a variety of sizes, speeds, and types. You can use them with different strapping materials such as plastic, steel, polyester, etc.

The basic use of these Strapping machines and tools is in the industries that deal with heavy loads. E.g. logistics, manufacturing, construction, etc. They make the process of securing products easier, faster, and safer. Proper strapping procedure prevents the splitting or falling of products during transport.

Let’s understand the working mechanism used in a strapping tool.

How Does a Strapping Machine Work?

Strapping machines generally work by detecting the product through sensors. Dispenser hold the strapping material which is then loaded on a pulley system. Mechanical spinners rotate and wrap the straps around product in a quick motion. Process used for loading and detecting differs in manual and automatic strapping machines.

The choice of strapping machine is made according to the product type and load volume. You must know the various types to determine which one is best suited for needs of your business.

Types of Strapping Tools

These are some common types of strapping machines and tools, each designed for different needs and uses.

1. Manual-Handheld Strapping Tools

These are small handheld tools that manually bind and secure the strapping around product. They are ideal for businesses with lower load volumes or pallets with specific strapping requirements.

Their common features include:

- Built-in dispenser

- Varied tension of strapping

- Complete manual procedure

- Process taking several minutes

- Binding of 20 pallets per day

2. Battery-Powered Handheld Strapping Tool

They are also lightweight and portable but require less labour than a manual tool. Battery strapping tools are suitable for medium-scale operations where efficiency and mobility is required.

Their features are as follows.

- Powered by a small battery

- Constant tension of strapping

- Simple method of application

- More speed and convenience than manual tools

- Weight of <10 pounds

- Strapping 100 pallets per day

Explore different types of handheld strapping tools from our collection.

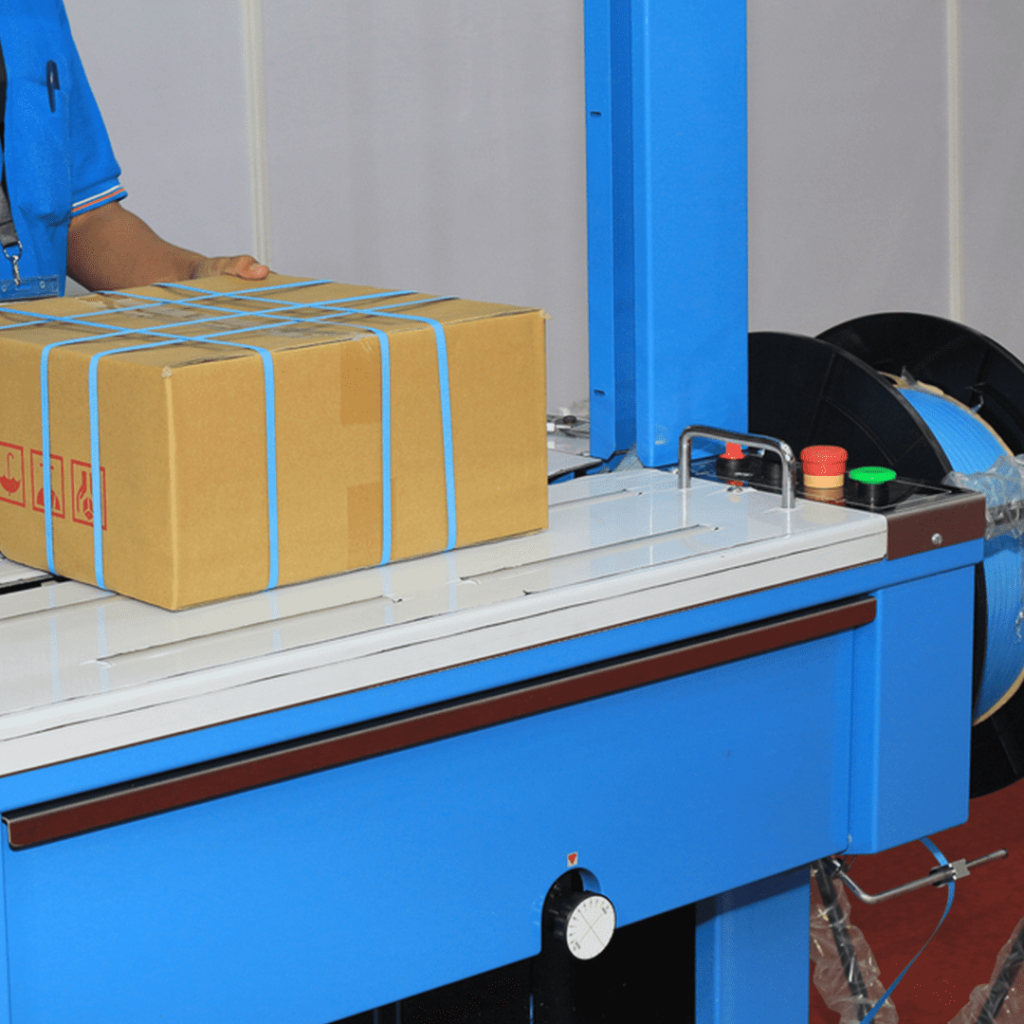

3. Semi-Automatic Tabletop Strapping Machine

These machines offer portability with better speed due to their semi-automatic mechanism. An operator is still required to feed the strap to machine. They are best for moderate production speeds.

Some of their characteristics include:

- Partial manual intervention

- Automatic tensioning

- Automatic sealing

- Capacity of 20 straps per minute

Explore our different models of semi-automatic strapping machines

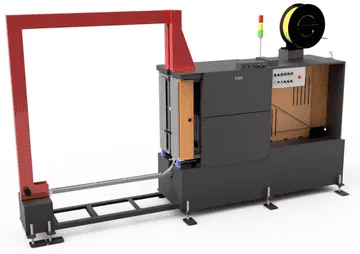

4. Arch Strapping Machine

Arch strapping machines rely even less on operator than a tabletop machine. They are used in higher volume operations. The size arch machine is decided by the common size of cartons dealt in your business.

They have the following features:

- separate, powered dispenser

- Semi-automatic or automatic function

- Up to 60 straps per minute

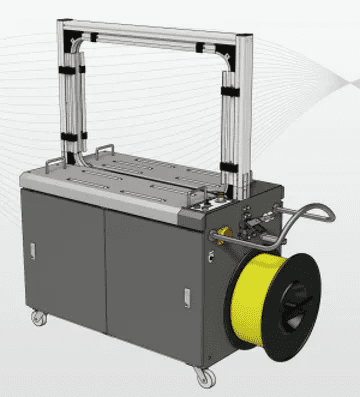

5. Automatic Strapping Machine

Automatic strapping machines feed, tension, and seal the strap around the product automatically. They save the highest amount of time and effort. Which makes them ideal for high-volume production lines.

- Expensive price

- Complete automation

- Use of photocells for getting new bundle

- Allow customisation with conveyors

- Continuous, high-speed packaging

- Up to 60 straps per minute

Explore our variety of semi-automatic and automatic strapping equipment.

6 Factors to Consider While Buying Strapping Equipment

When you are going to choose suitable strapping equipment for your business, keep the following factors in mind.

1. Volume of Production

First question while choosing a strapping tool is, how many shipment boxes you dispatch per day? Can a handheld tool manage that number? Or a large machine is required?

Businesses dealing with high volume of shipments should opt for auto strapping machine. As they can manage faster and more efficient operations. For smaller number of shipments, a simple battery-operated tool will suffice.

2. Product Size and Weight

Different machines and strapping materials are selected according to product sizes and weights. Take the measurements of products you commonly deal with, & then go for a strapping tool. Smaller boxes can be strapped by a handheld strapping tool. Whereas, large shipments require a machine.

Heavy-weighted and denser products also require stronger strapping materials, like steel strapping, and more durable machines.

3. Type of Strapping Material

The material you use for strapping, like plastic, polyester, or steel, also have a huge role deciding type of equipment. Plastic strapping can go with any type of strapping equipment. But heavier strapping like steel will require a heavy strapping machine.

Before buying, make sure that your strapping machine is compatible with the length, width, and gauge of strapping you plan to use.

4. Space Availability

Another important factor is size of your warehouse and space you can allot for packaging. It will help in ruling out some options.

Since the machines can range in size from small tabletop unit to large fully automated setups. Knowing where the machine will be placed in your environment is extremely important when assessing options.

5. Workforce Skill Level

Use simpler machines if your team is not experienced in operating complex systems. E.g. an arch strapping machine allows simpler settings than an advanced version with conveyors.

Automated strapping tools usually require prior training. While semi-automatic machines are user-friendly. They can be easily managed by average warehouse workers.

6. Your Packaging Budget:

While automatic strapping machines may be a larger upfront investment, they can offer cost savings in the long term through increased speed and efficiency. It’s important to balance your budget with the operational benefits the equipment will provide.

Once you have chosen a specific strapping tool, let’s talk about some tips to use it efficiently.

10 Important Tips for Buying and Using Strapping Machines:

Remember the following expert tips whether you are going to invest in strapping equipment or already using it in your warehouse.

- Buy a strapping tool built with high-quality materials. So, it can easily withstand daily industrial use.

- Choose easy-to-maintain equipment having readily available parts to avoid long downtimes.

- Consider the speed of strapping machine and if it can handle your volume without causing production delays.

- Each machine comes with specific operating instructions. Make sure your team is trained in these guidelines to prevent accidents.

- Instruct the staff to use gloves and safety goggles when handling with strapping equipment. It will protect them from sharp edges or sudden tension release.

- Always check the voltage and only use the instructed electric power to keep the strapping tool safe.

- Make sure that the machine space doesn’t contain any type of tools, debris, or unwanted objects.

- Never put any part of your body near, under, or into a moving machine. Don’t even try to touch with your hands after setting it to work.

- Make the working staff read and understand all signs inscribed on the strapping equipment. Replace the sign in case of any damage.

- Inspect the equipment regularly to make sure it is operating correctly. Routine checks reduce the risk of malfunctions.

Conclusion

Choosing the right strapping equipment is a decision that can directly impact your packaging operations. From manual tools to automatic strapping machines, the right choice depends upon your production volume, product type, and company budget.

By understanding the types and considering the key factors, you can choose a strapping equipment of your choice. It will improve production efficiency, reduce costs, and enhance the safety of your operations.

Looking for efficient and easy-to-manage strapping machines for your business?

Get Quality Packaging Solutions with All Pack Tech

If you’re looking for durable, high-quality strapping equipment to manage your packaging demands, we have the perfect solution for you.

We, at All Pack Tech, are the trusted supplier of packaging machinery in Australia since 2000. We have a strong track record in helping businesses streamline their operations through high-quality packaging machinery.

Be it a simple battery strapping tool or an auto strapping machine, we have the right type of products for you.

Get a quote for Strapping products of your choice.

Explore the collection of our packaging equipment.

Let’s make sure your next shipment is secured with confidence!