Why Stretch Films Beat Other Packaging Methods? 8 Benefits

It’s no secret that shipping and storage is the real headache for businesses.

Damaged goods, wasted material, and slow packing processes all eat into profits and frustration. Companies struggle with the ways to speed things up, cut costs, and keep items safe in transit.

If that’s the case with you too, good news! We have a simple solution to all these problems of industrial packaging, and it is called a “stretch film”.

Since 2000, Allpack Packaging Technologies has been helping businesses tackle the packaging challenges. Our bag sealing machines, stretch films & pallet wrap systems, all help you in safe packaging & transit.

We’ve seen how much smoother a stretch film can make your operations. And we’re excited to share its secret talents with you.

What Is Stretch Film?

Stretch film, also known as stretch wrap, is a highly stretchable plastic film used to secure products on pallets. It is made from LLDPE (linear low-density polyethylene), that wraps around goods to keep them tightly bound.

So, there is no shifting, tipping, or breakage during handling and transport. Unlike strapping, shrink wrap, or carton packaging, stretch film uses tension to lock products in place. You can apply it by hand or via a machine, and it will not let your products go loose.

Types of Stretch Films

According to the needs and scale of your industrial packaging, you can choose:

Type | Detail |

Hand Pallet Stretch Wrap Rolls | Designed for manual wrapping Perfect for businesses with smaller packaging volumes |

Machine Stretch Film | Applied with pallet wrapping machines for high-volume operations Give consistent wrapping |

Blown Stretch Film | Stronger and puncture-resistant Suitable for heavy or irregular loads |

Cast Stretch Film | Clear and smooth Used for product visibility and quiet unwinding |

Pre-Stretched Film | Pre-stretched before application Offer high tensile strength and reduced material use Cost-effective in the long term |

You can get hand pallet stretch wrap for occasional use or a high-performance pallet wrap and stretch film for automated systems. They all can keep your products safe and deliver exceptional results.

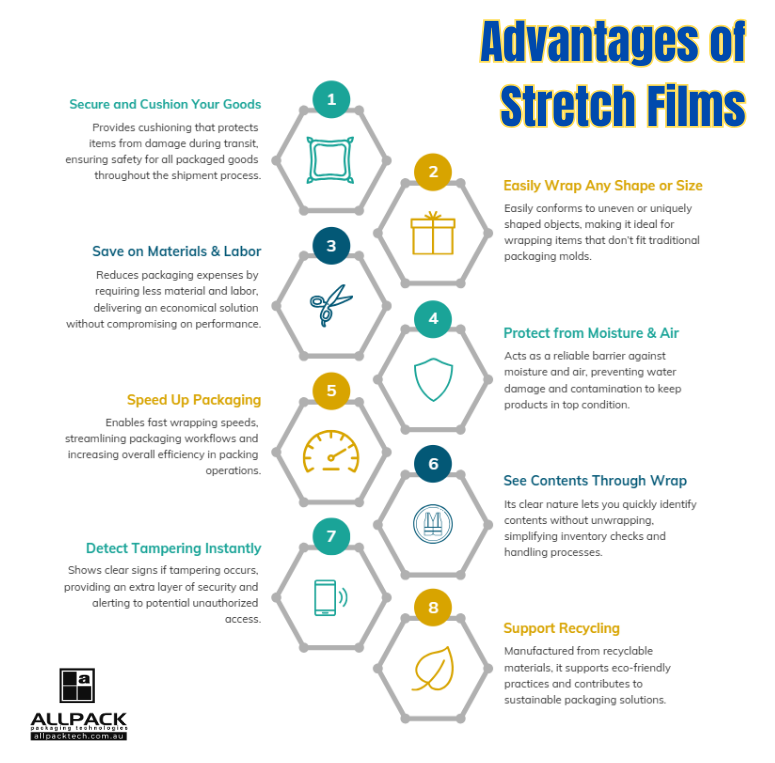

Advantages of Stretch Film Over Other Packaging Methods

Let’s discover why stretch film & pallet wraps are preferred over other packaging methods & techniques.

1. Protection and Safety

Stretch film keeps products secure and stable on pallets. It prevents goods from toppling, sliding, or being damaged during handling and transport. Compared to strapping or shrink wrapping, stretch film applies even pressure without crushing items. So, it is a safer option for fragile or oddly shaped products.

Plus, it doesn’t cut into the load, and it minimizes injury risks during application

2. Flexibility

Because stretch film adapts to any shape, so, there’s no need for custom boxes or rigid covers. Doesn’t matter if you’re wrapping small cartons or large machinery, it stretches to cover them easily.

This adaptability lets you wrap odd-sized or irregular loads without multiple packaging materials. So, a lot of time and storage space is saved.

3. Cost Effectiveness

One of the biggest advantages of stretch wrap is its affordability.

It is cheaper than alternatives like shrink wrap, corrugated packaging, or strapping. Plus, its efficient application means less waste and more value over time. Hence, businesses that buy stretch wrap in Australia find it more cost-effective in the long run, especially when paired with an efficient pallet wrapping machine.

4. Moisture & Air Barrier

Stretch films act as a protective shield that guards against environmental factors. E.g. dust, moisture, and air exposure. This protection is particularly important for food, pharmaceuticals, and electronics. Unlike cardboard or strapping, stretch wrap keep perishable items safe with its sealed layer.

UV-inhibiting specialty films can provide extended protection for outdoor-stored goods too.

5. Wrapping Efficiency

Stretch film packaging is quick and easy. With hand pallet stretch wrap rolls, workers can wrap multiple items quickly and securely. For higher volumes, automated wrapping machines make the process even faster. Hence, labour time is saved with improved consistency.

So, you can get smoother operations, enhanced productivity and fewer delays in shipping.

6. Transparency

Unlike opaque packaging, stretch films are clear, so you can see what’s wrapped.

This transparency allows easy identification of products without unwrapping. So, there is better warehouse management, stock control, and quick inspections. It also reduces errors in order fulfilment and makes goods reach the right customers.

7. Tamper Protection

Stretch wrap makes it easy to detect tampering.

Any attempt to cut, remove or damage the film is immediately visible. So, it is a big advantage & additional security for businesses transporting high-value goods. There is no chance of theft or swapping of goods as compared to boxes or strapping.

8. Recycling

Modern stretch films are recyclable. So, they are more sustainable & eco-friendly than traditional packaging methods.

By recycling used wrap, businesses can reduce waste and lower their environmental footprint. Some advanced films are also made with recycled materials, contributing to greener packaging practices.

Use Cases for Stretch Films & Pallet Wrap

Stretch film is used across a wide range of industries. Because for every business that need efficiency and reliability in their packaging, it offers practicality and performance that alternatives can’t match.

Industry | Use of Stretch Film & Pallet Wrap |

Food and Beverage | Keeps cartons of drinks and packaged food stable and protected during transport. |

Pharmaceuticals | Keeps medicines and medical supplies secure, clean, and uncontaminated. |

Retail and Distribution | Wraps mixed-load pallets for safe, efficient delivery and reduces handling errors. |

Manufacturing | Protects machinery parts and raw materials from dust, dirt, and moisture. |

Logistics & Warehousing | Simplifies pallet storage, reduces product movement, and improves stacking efficiency in warehouses. |

From small operations using hand pallet stretch wrap to large warehouses with automated systems, stretch film is a versatile solution for every packaging challenge.

Looking for Efficient Packaging Solutions for Your Business?

Buy Stretch Wrap Australia at Allpack Packaging Technologies

We supply everything from hand pallet stretch wrap rolls to advanced stretch packaging machines designed for heavy-duty industrial use. Our focus is on delivering durable, efficient equipment that helps you reduce downtime and increase productivity.

If you’re ready to upgrade your packaging process,

Explore Our Range of Stretch Films & Pallet Wrap Solutions

Let’s make your packaging smarter, safer, and more efficient.