Banding vs Strapping Machine: Which One Should You Choose?

So, you’ve got products. Boxes & pallets piled high and orders flying out the door. But how are you holding all this stuff together? Duct tape? Machine stitches? No, my friend. It’s time to get serious.

You need the right machine to bundle, bind, and boss-up your packaging. And that means choosing between a banding machine or a strapping machine. So, how do you make the decision? Which factors to consider?

We’ve simplified everything in this comparison guide by Allpack Packaging Technologies. Just note the plus points of each option and choose the best one for your business.

Starting with the basics.

What is a Strapping Machine?

Strapping machine is a specialised device to secure packages or bundles. It uses a tensile strap to be applied tightly around items and fastened using:

- Heat sealing

- Friction welding

- Metal seals

The main purpose is to keep items stable, aligned, and secure during handling or transit. Be it sealing cartons, stabilising pallet loads, or bundling steel rods. This machine acts like a workhorse in industrial settings.

If your operation handles heavy, awkward, or high-volume loads. It can significantly reduce time and improve safety during packaging. Plus, it also helps optimise warehouse space, reduces shipping damage & increases productivity.

Types of Strapping Machines

At Allpack Packaging Technologies, we categorise strapping machines based on their operation method and intended usage. E.g.

- Manual strapping tools

Ideal for low-volume, portable use. They include tensioners and sealers operated by hand, used in fieldwork or remote warehouses. - Semi-automatic strapping machines

Suitable for mid-level packaging needs. The operator positions the strap and the machine completes the tensioning and sealing. - Fully automatic strapping machines

Best for high-speed production lines. These machines strap, seal, and cut with little to no human input, & improve output dramatically. - Pallet strapping machines

Designed specifically for securing palletised loads. These tools help apply vertical or horizontal straps with consistent tension. - Tabletop models

Compact and easy to use. They are used in retail or light manufacturing for small packages and are easy to integrate into existing packing tables.

Each model varies in speed, durability, and tension capabilities. Choosing the right one depends on your throughput, product size, and strapping material (polypropylene, polyester, or steel).

Now moving toward the second option.

What is a Banding Machine?

A banding machine is used to bundle products with a thin strip of paper or plastic. It is applied with a mild tension that avoids crushing or damaging items. These strips, known as bands, are sealed using heat or ultrasonic bonding & form a neat & secure wrap.

What sets them apart is their focus on presentation and gentleness. Commonly found in the:

- Printing

- Food

- Cosmetics

- Pharmaceutical industries

They offer a clean & aesthetic finish without compromising the product’s shape or surface. Imagine stacks of greeting cards, a set of wrapped brochures, or a pack of surgical gloves. These machines keep them uniform without over-compression.

They also excel in environmentally sensitive industries. Since paper bands are recyclable and compostable. This process is viewed as a sustainable packaging choice.

Types of Banding Machines

There’s a wide range of banding equipment for different packaging volumes and product types. Common varieties include:

- Manual banding tools

Basic hand-operated tools for very low output needs or small businesses. - Semi-automatic machines

Versatile and compact machines which require an operator to place the product. But the banding is applied and sealed automatically. - Fully automatic machines

Integrated into large-scale production lines, these high-speed machines handle precise & repetitive bundling with minimal downtime. - Edge banding machines

Though unrelated to bundling, this term refers to machines used in furniture making to apply edge strips to boards.

Depending on the model, bands can be printed with logos or barcodes. So, there can be a better brand visibility and traceability during distribution.

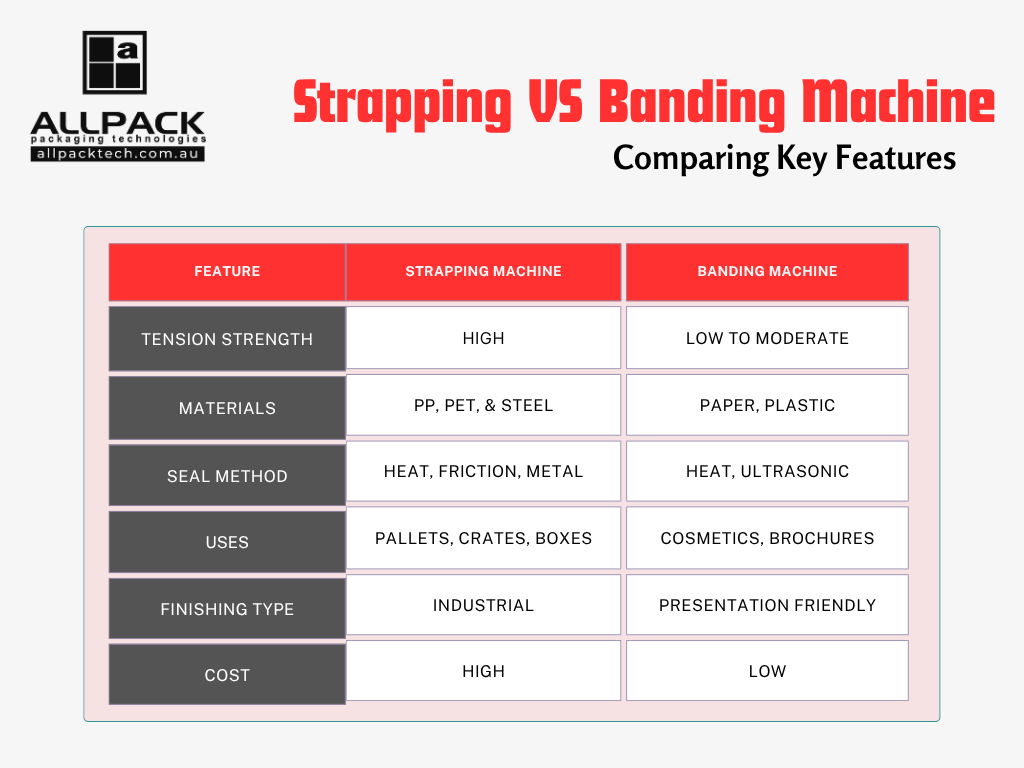

Strapping vs Banding Machine: Key Differences

Let’s find out the best option by a detailed analysis of key differences. The table below gives you a snapshot, followed by more context.

1. Working mechanism

Strapping machine uses mechanical tension and precise alignment to tightly apply the strap. Depending on the model, they use friction welding or heat sealing to bond the strap ends.

In contrast, banding machines gently apply a narrow band around the product. Overlapping the ends and sealing them without exerting much force. So, packaging remains intact but not compressed.

2. Speed

If speed is your priority, automatic strapping machines win. Built for high-volume operations and can strap thousands of packages per day without error. They can be adjusted for different sizes and run continuously.

While banding machines operate at slightly lower speeds. That said, they make up for it in precision and presentation. For smaller or more delicate products, banding is faster because it requires less handling.

3. Range of Materials

Strapping allows for a wider range of materials, especially those built for strength, like:

- Polypropylene (PP): Lightweight and economical.

- Polyester (PET): Strong and stretch-resistant.

- Steel: Heavy-duty industrial applications.

Banding, meanwhile, favours materials suited to appearance and product care:

- Kraft paper: Used for eco-friendly bundling.

- OPP plastic film: Transparent, smooth, and neat.

Some machines are compatible with printed bands for branding or compliance.

4. Ease of use

Banding machines are plug-and-play & require minimal training. Operators simply place the product, and the machine takes care of the rest.

Strapping machines have a steeper learning curve. As they involve multiple configurations & need adjustments for multiple projects.

5. Applications

Banding machine is used in:

- Bundling of brochures or printed media

- Wrapping cosmetic items for shelf display

- Light food packaging like herbs, chocolates

- Grouping pharmaceutical products in clinics

On the other hand, uses of strapping machine include:

- Securing heavy boxes or crates

- Stabilising pallet loads before freight

- Binding building materials like timber or pipes

- Ensuring cartons remain shut during transport

If you need to secure items with substantial weight or risk of shifting, strapping is essential. For grouped retail products, choose banding.

6. Price

Strapping machines have a higher upfront cost, especially for fully automatic models. However, they pay off in the long run with reduced labour, fewer errors, and packaging reliability.

Banding machines are more affordable, especially for businesses focused on presentation packaging or handling lower weights. Also, they consume less energy and only suitable for lighter materials like paper.

Is Banding a Better Alternative to Strapping?

In many cases, no. Banding is not a one-to-one replacement for strapping. They serve different packaging needs, and should be treated as separate entities.

Banding is better when:

- Your products are fragile & lightweight.

- You require better presentation & visual appeal.

- You need branding or barcoding on packaging.

- Space-saving, recyclable packaging is a priority.

Strapping is better when:

- Your packages need to be immobilised.

- You deal with freight or warehousing.

- You require high tension and secure seals.

- You are packaging industrial loads.

The best decision balances cost, appearance, functionality, and product safety. Some high-scale businesses & industrial setups use both for the variety of products. Strapping for outbound logistics and banding for shelf-ready packaging.

Searching for the Right Strapping & Stapling Machines and Tools?

Talk to the Experts at Allpack Packaging Technologies

We are the trusted packaging partners you need for your business. For over two decades, we helped businesses across Australia with durable, efficient, and smart solutions.

From pallet wrapping machinery to custom-built strapping machine equipment in Perth. Our team can offer practical insights and industry-best solutions for your business. So, you can find custom machinery according to your workflow.