Key Features to Look for in Quality Carton Sealing Machines: Expert Guide 2025

Sealing cartons isn’t much of a job when you’re handling a small number of boxes. But once the production volumes rise, it becomes a bottleneck. Because no business can afford inconsistent tape application, mis-aligned flaps, and weak seals.

If you’re operating a busy packaging line in Australia and want to minimise downtime and maintain a secure and strong seal, don’t rely on hand-taping.

What to do instead? Get carton sealing machines for better efficiency & faster throughput.

At Allpack Packaging Technologies we know how the right machine can integrate into your line and deliver a secure and strong seal for every order. As our team is supplying high-quality packaging equipment to Australian businesses for decades.

Let our experience guide you on everything about carton sealing machines.

What Is a Carton Taping Machine?

Carton sealing or taping machine is an equipment designed to apply adhesive tape (or glue) to the flaps of a corrugated carton after it has been filled. Rather than using a handheld dispenser and manual effort, the box is placed on a conveyor or feeding system and machine handles the sealing of flaps.

So, you can get consistent seal quality, improved throughput and reduced reliance on manual labour. These machines are essential when production grows and manual effort can’t keep up to the supply demands or maintain uniformity.

How Do Carton Sealing Machines Work?

The basic workflow of a carton sealer is broadly the same across all models. But good machines have well-engineered components and optimised flow to maximise packaging efficiency. Let’s have a look at their functioning.

| Step | Detail |

| Carton feeding | The filled carton enters the machine (manually or automatically) via a conveyor or set of rollers. |

| Flap closure | Machine adjusts to the carton’s dimensions and the top and/or bottom flaps are closed (manually or by a pre-flap closing device). |

| Drive belts / rollers | Carton is driven through by belts, which stabilise the box and carry it through the tape heads. |

| Tape application | The tape head applies pressure and adhesive along the seam, and create a secure and strong seal to survive transport. |

| Exit | The sealed carton exits onto a conveyor or stacking area, ready for labelling or palletising. |

Modern machines include sensors, PLC controls and automatic size detection to adjust to different carton dimensions.

Different Types of Carton Sealers

There are several categories of carton sealing machines depending on functionality and mode of work. Note the differences, so, you can pick the right machine for your operation.

- Semi-automatic Carton Sealers

The operator feeds and positions the carton (after flap folding) and the machine applies the tape automatically. It is used for small to medium operations with moderate volume. - Fully Automatic Carton Sealers

These machines automate the feeding, flap folding, size detection and sealing without any operator. They are suitable for high volume production lines with speed requirement and minimal manual intervention. - Uniform Carton Sealers

The machine doesn’t adjust to the different box sizes. It is designed for operations where cartons are of the same size. Fast setup and minimal adjustment. - Random Carton Sealers

These machines can accommodate a variety of box sizes and adjust width/height automatically or with minimal manual input. They are useful in flexible packaging lines. - Drive Belt Configurations

So, how do you find out which type of carton sealer is suitable for your business? Let’s check out their features and find how can you match these features to your needs.

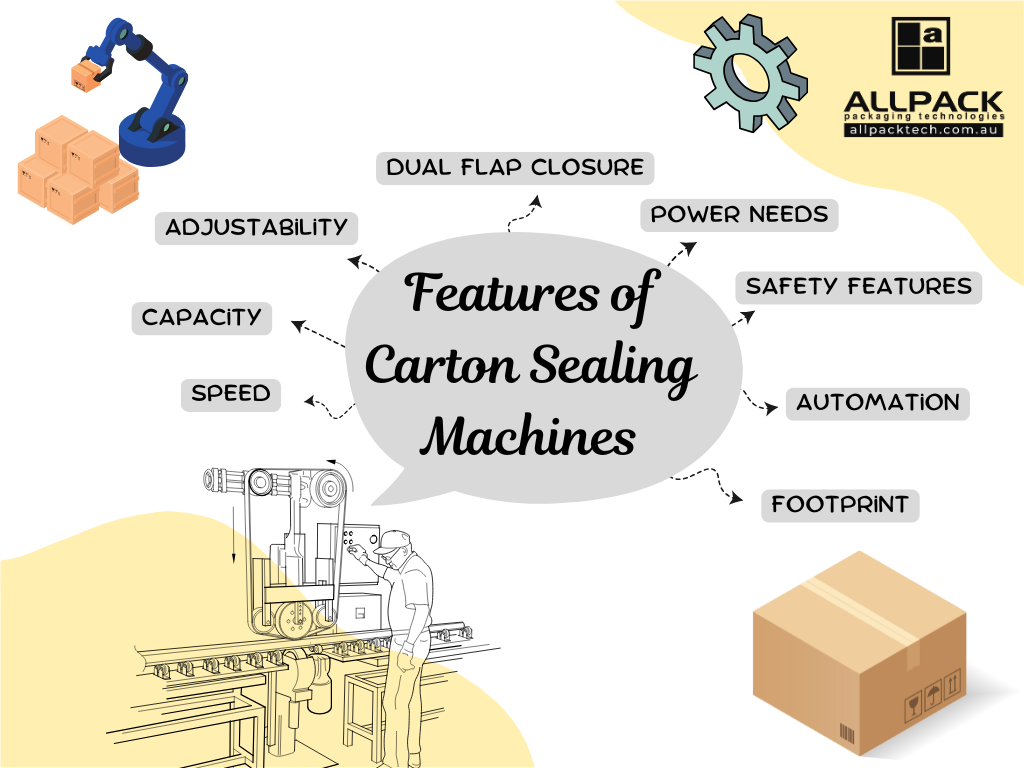

How to Choose a Carton Taping Machine? Key Features to Look For

When selecting a carton sealing machine, you should evaluate a number of features. Some of them are obvious, while others are less so. But all of them contributes to find a machine that fits your workflow, enhances efficiency and gives consistent results.

1. Capacity

It means how much cartons can be sealed at once.

So, you need to consider how many cartons per hour you seal. Machines that are too slow become bottlenecks, and too fast ones waste the investment. Semi-automatics handle tens of cartons per minute, while fully automatic lines can handle many more.

2. Top & Bottom Sealing (Dual Flap Closure)

If you apply tape only to the top of the box, the bottom remains a potential weak point.

Machines with both top and bottom sealing give better reliability for shipping heavier loads or international orders. Dual belts or top & bottom drive configurations improve box stability during sealing. Plus, you can change them to be single whenever needed.

3. Speed

It refers to how many units you can produce per hour or minute

A machine’s belt speed and throughput affect your packaging efficiency. For example, some models run at around 20 m/min (≈30 cartons per minute) for uniform boxes. Get a machine with speed equals to your peak demand without sacrificing the quality of seal.

4. Power Needs

Power need is defined by amount of force required during sealing operations.

Check the voltage, phase and overall power consumption, before purchasing a model. Some machines require three-phase power; others operate on single phase. The right power configuration avoids surprises in installation and operational cost.

5. Adjustability

It measures the machine’s ability to adjust with different bag dimensions.

If your business uses cartons of different sizes, you’ll need quick height/width adjustment or automatic size detection. Automatic or tool-free adjustments will keep your system moving. Some models even have adjustable speeds as per your work flow.

6. Safety Features

Reliable machines include emergency stop buttons, guards, safe access, and sensors to prevent jams and protect operators. Modern systems also integrate automatic shutdown for safety and energy saving. Check these features to minimise workplace injuries.

Also verify that the machine complies with the safety standards in your region.

7. Integration with Conveyors or Automation

To maximise packaging efficiency, your sealer should integrate easily with upstream and downstream equipment. E.g. conveyors, case erectors, labellers, and palletisers. It’ll help you build a smooth end-to-end packaging line.

Choose the carton sealer with more automated function if you want to cut on labour.

8. Footprint and Build Quality

A machine built with high-grade materials (e.g., stainless steel frame), durable belts and good serviceability will reduce downtime and increase life span. Hence, they will help you in meeting sustainable business goals.

Get energy-efficient machines to reduce your carbon footprint and save on utility bills.

Recommended Corton Sealers for You

Our range at Allpack Packaging Technologies include several models of the Packway Carton Sealers, known for reliable & industrial-grade construction.

Here are our top models that you should consider.

| Model | Type | Best For | Features | Why Choose It |

| Packway Model PW-554TS | Top and bottom belt drive | Uniform carton sizes | Adjustable table height, side belt drive for stability, simple tape head replacement | For consistent sealing jobs. Offers excellent performance for light to medium loads and offer smooth & precise taping. |

| Packway Model PW-562M | Random carton sealer | Mixed-size cartons | Automatic adjustment for height and width, high-speed operation, stainless-steel frame | For dynamic packaging lines handling varied box dimensions. It reduces setup time and boosts productivity. |

| Packway Model PW-557F | Top and bottom sealer | Heavy-duty cartons | Dual-motor drive, reinforced frame, easy tape loading | For demanding applications where durability and a secure seal is needed. Handles the high-volume production. |

Looking for a Durable Carton Taping Machine for Your Business?

Get Efficient Carton Sealing Machines at Allpack Packaging Technologies

At Allpack Packaging Technologies Pty Ltd, we’ve been serving Australian manufacturers and distributors since 2000. Our high-quality packaging equipment delivers consistent & reliable results for all your business needs.

From carton sealing machines to strapping systems and fully automated lines, our equipment is built to deliver reliable packaging, smooth operations and consistent performance. Our team provides expert advice to match machine to your workflow.

Plus, we also offer ongoing service and support to keep your business running smoothly.

Want to explore which carton sealer is best for your facility

Contact Our Friendly Perth-Based Team Today

Check Out Our Full Range of Carton Sealers

and learn how we can help you pack faster and smarter.