Impulse Sealers | Everything You Need to Know About Bag Sealers

Ever wondered how manufacturers create those perfectly sealed plastic bags that keep food fresh, prevent leaks, or protect delicate items? The secret lies in impulse sealers. The versatile and efficient packaging machines designed to seal plastic bags with precision.

Are you a small business owner packaging products? A warehouse operator handling bulk sealing? Or just someone curious about how these heat-sealing machines work? No matter your background, you’re in the right place.

In this guide, we’ll explore everything you need to know about impulse sealers. From how they work and the different types available to step-by-step instructions on using them like a pro. Additionally, we’ll highlight the top impulse sealers of 2025 to help you choose the best one for your needs.

Impulse Sealers Explained | How They Work & Why You Need One

Impulse sealers are powerful packaging tools that secure and airtight seal the plastic materials like poly bags and stand-up pouches.

Whether you’re preserving food, protecting products, or ensuring leak-proof packaging, these machines make the job effortless.

So, how do impulse sealers work?

Impulse sealers use a quick burst of electricity to heat a metal wire, which melts the plastic layers together and forms a strong, tamper-proof seal. Unlike constant heat sealers, they only generate heat when activated. This makes them energy-efficient and safe to use.

Once sealed, the plastic won’t open unless it’s cut, ensuring a tight, professional finish. These machines are easy to operate. But proper training is essential to achieve consistent, high-quality results.

5 Common Types of Impulse Sealer

Impulse sealers come in various designs. Each suited for different packaging needs. Whether you’re sealing small batches at a workstation or handling high-volume sealing in a warehouse, there’s a type that fits the job perfectly.

Here’s a breakdown of the five types of impulse sealers and what they’re best used for:

Type | How It Works | Best For |

Tabletop Impulse Sealer | Resembles a stapler; manually pressed down to seal plastic bags. | Small businesses, home use, and low-volume sealing. |

Mounted on a stand; uses a foot pedal to activate the seal. | Medium to high-volume packaging; hands-free operation. | |

Double Impulse Sealer | Uses dual heating bars for extra-strong seals on thick materials. | Heavy-duty packaging like automotive parts, machinery, and industrial applications. |

Impulse Sealer with Cutter | Seals and trims excess plastic in one step. | Plastic tubing, shrink-wrap bags, and packaging that requires clean-cut seals. |

Automatic Impulse Sealer | Fully automated; programmable sealing times and temperatures. | High-speed production lines and large-scale packaging. |

Each type has its advantages depending on your sealing needs, material thickness, and volume. If you’re sealing small batches, a tabletop sealer is perfect. Need hands-free efficiency? Go for a foot-operated one. Working with extra-thick plastics? A double impulse sealer is your best bet. No matter the type, impulse sealers help streamline packaging, ensuring secure and professional-quality seals every time.

Up next, let’s talk about how to use a manual impulse sealer like a pro.

How to Use an Impulse Sealer for Perfect Bag Sealing | 6 Simple Steps

Sealing plastic bags with an impulse sealer is quick, efficient, and easy. But getting that perfect, airtight seal requires a bit of know-how. Following the right steps ensures a strong, professional-quality seal every time.

Let’s walk through the step-by-step process to help you get the most out of your impulse sealer.

Step #1. Pick the Right Heat Sealer for Your Needs

Before you start, make sure you’re using a sealer that matches your packaging needs. Impulse sealers come in various types and sizes. So, picking the right one will save time and improve sealing quality.

Key Factors to Consider:

- Bag Size: A small sealer works for small bags. But larger items need a longer sealing bar.

- Material Thickness: Thicker plastic requires a more powerful or double impulse sealer.

- Seal Width: Most standard sealers have a 2mm seal. But a 5mm seal is better for extra durability.

- Frequency of Use: For high-volume sealing, an automatic or foot-operated model is ideal.

- Cutter Feature: If you’re working with plastic tubing, a built-in cutter will save time.

Pro Tip: If you’re unsure which sealer to choose, test a few samples with different sealing widths and timers to see which works best for your packaging needs.

Step #2. Set Up Your Workspace

A good setup makes sealing faster and safer. Place your impulse sealer on a clean, flat surface, away from liquids or anything flammable. Keeping the area clutter-free prevents mistakes and ensures smooth operation.

Make sure the sealer is positioned at a comfortable height to avoid strain while using it. Also, check that the power cord is in good condition and plugged into the correct voltage outlet.

Step #3. Prepare the Bag

To get a strong, secure seal, your bag needs to be clean and smooth before sealing. Any dirt, moisture, or wrinkles can cause weak spots, leading to leaks or poor packaging. So, you make sure:

- the bag is free of dust or debris

- lay it flat and remove any wrinkles

- the product inside is evenly distributed

If you’re sealing multiple bags, take a moment to align each one properly before placing it in the machine. A little preparation goes a long way in ensuring consistent and high-quality sealing.

Step #4. Adjust the Sealing Time

One of the best features of an impulse sealer is its adjustable sealing time. This lets you customise the heat level based on the type and thickness of your plastic.

Thin bags? A short sealing time works best. Thick bags? Increase the sealing time for a firm bond. Test first! Before sealing multiple bags, do a test run to find the perfect timing.

You’ll find the seal timer knob at the front of the machine. Start with a lower setting and gradually increase it until you achieve a strong, airtight seal. Heat and humidity can affect seal time. So, adjust accordingly.

Step #5. Seal the Bag

Now that your bag is in place and the timer is set, it’s time to seal. Here’s how you do it:

- Insert the open end of the bag between the sealing bars

- Press down firmly on the handle or foot pedal

- Watch for the indicator light. This means the machine is heating

- Hold the handle down until the light turns off

- Wait a few seconds before releasing to let the seal set

This quick process creates a strong, tamper-proof seal that keeps your product safe and secure.

Step #6. Inspect Your Seal

Before storing or shipping your product, double-check the quality of your seal.

- Is the seal even and fully closed?

- Are there any gaps, wrinkles, or weak spots?

- Does the bag hold air without leaking?

If the seal looks incomplete or weak, adjust the seal time or handle pressure and try again. Regularly inspecting your seals also helps identify maintenance needs, such as a worn-out heating element.

The BEST Impulse Sealers of 2025 at Allpack Packaging Technologies

We offer a range of high-performance impulse sealers designed for efficient, secure, and professional packaging. Whether you need a compact handheld sealer or a long-handle model for large bags, we have the perfect solution for your needs.

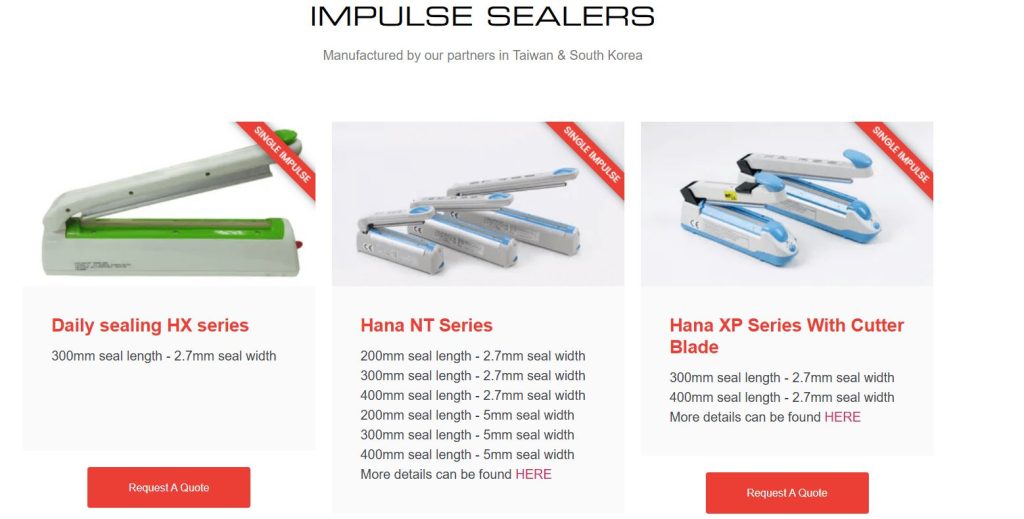

Check out some of the top-rated impulse sealers of 2025:

Sealer Model | Seal Lengths | Seal Width | Type | Special Features |

Daily Sealing HX Series | 300mm | 2.7mm | Single Impulse | Reliable & versatile |

Hana NT Series | 200mm, 300mm, 400mm | 2.7mm, 5mm | Single Impulse | Multiple size options |

Hana XP Series With Cutter | 300mm, 400mm | 2.7mm | Single Impulse | Includes cutter blade |

Daily Sealing Long Handle | 600mm, 750mm, 900mm, 1000mm | 5mm | Single Impulse | Extra-wide seals + cutter blade |

Daily Sealing H Series | 300mm | 5mm | Single Impulse | Portable & easy to use |

Daily Sealing HT Series | 200mm, 300mm, 400mm | 5mm | Double Impulse | Stronger seals for thick bags |

Need expert advice? Talk to your trusted heat sealers supplier at Allpack Packaging Technologies for the best options.

Impulse Sealers vs. Heat Sealers: What’s the Difference?

If you’re wondering whether impulse sealers and heat sealers are the same, the short answer is no—they work differently and are suited for different packaging needs.

Impulse sealer uses short bursts of electricity to heat the sealing wire just long enough to melt and fuse the plastic. Once the seal is formed, the machine immediately cools down. There’s no need for warm-up time. It only consumes power when in use. This makes impulse sealers a go-to choice for sealing poly bags, mylar, bubble packs, and Tyvek materials.

Impulse sealers are also safer to use because the heat is only generated when the sealing jaws come together. So, there’s little to no risk of burns, making them ideal for workplaces that prioritize safety. Additionally, since the heating element is only active for a few seconds at a time, they are more energy-efficient, helping you save on electricity costs.

On the other hand, a heat sealer maintains continuous heat on both jaws and stays powered as long as the machine is switched on. This constant heat allows for better penetration, making heat sealers the better choice for sealing thicker materials like kraft paper, aluminum foil, gusseted bags, and cellophane. While modern heat sealers come with protective barriers to prevent burns, they do require more energy to operate.

So, which one should you choose?

- If you’re sealing lightweight plastic materials and want a quick, energy-efficient option, an impulse sealer is your best bet.

- If you need strong, airtight seals on thicker packaging, a heat sealer is the way to go.

Looking for impulse plastic bag heat sealers for your business?

Find Top-Quality Impulse Bag Sealers at Allpack Packaging Technologies

If you’re looking for a reliable heat sealers supplier, it’s essential to choose one that offers high-quality products and expert advice.

Allpack Packaging Technologies provide top-tier impulse heat sealers tailored to your packaging needs. As trusted packaging experts, we ensure that you get the best equipment to streamline your sealing process.

Contact us today. We’ re your go-to packaging suppliers in Perth. Explore our range of heat sealers & impulse sealers today.