PP vs. PET Strapping: Choosing the Perfect Packaging Material for Your Load

If you deal with the packaging of goods. You will be aware of the importance of strapping material. PP and PET strapping are two of the most popular choices in the industry. Both get the job done but differ in their properties, applications, advantages, and drawbacks.

So how do you pick the right strapping material for your business?

Let us simplify the PP vs. PET strapping discussion for you. We’ll compare material chemistry, strength, tension retention, handling, cost of ownership, recycling, and tool compatibility. So, you can make the best choice for your packaging needs and, of course, keep your products safe and sound during transit.

At Allpack Packaging Technologies, we supply high-quality packaging equipment and materials to Australian businesses, helping them improve the efficiency and safety of their goods. We have the equipment for your lightweight products as well as heavy-duty shipments.

Let’s start the comparison.

What is the Difference Between PP and PET Strapping?

PP (polypropylene) is a lightweight, low-cost strap best for short-term, light-to-medium loads and manual/semi-automatic use. PET (polyethylene terephthalate) is a polyester strap built for higher strength, lower stretch, and long-term load stability; it is ideal for heavy pallets, long-haul transport, and automated systems.

Keep reading to explore the detailed breakdown:

What is PP Strap?

PP strap is a lightweight thermoplastic strap commonly used for carton closing, light palletizing, bundling, and general packaging where cost and handling ease matter. It’s flexible, available in a range of widths and colours, and is often printed for branding.

Benefits of PP Strapping:

- Low cost per roll

- Flexible and forgiving on irregular loads

- Easy to apply manually or with semi-automatic equipment

- Available in many widths/colours and printable for branding

Considerations:

- Lower tensile strength and less tension retention than PET

- Can relax under sustained tension

- Less weather/UV resistance

What is PET Strap?

PET strap is a polyester strap engineered for higher tensile strength, low stretch, and excellent tension retention. It’s commonly used as a safer, lighter alternative to steel for many palletized loads and performs well in automated strapping systems.

Benefits of PET Strapping:

- High tensile strength and low elongation (minimal stretch)

- Excellent long-term tension retention; ideal for long storage/transit

- Good resistance to weather and UV; suitable for outdoor exposure

- Compatible with automated strapping systems and battery tools

- Available in PET (recycled) grades

Considerations:

- Higher cost per roll than PP (but lower lifecycle cost for heavy use)

- Less flexible for pure hand-applied situations

- Requires compatible sealing/tension equipment to achieve best performance

Understanding each material on its own is useful, but the best way to choose is to compare the key features side-by-side. Below are the seven attributes that matter most.

PP vs. PET Strapping: Top 7 Features Compared

1. Material & Composition

1. PP (polypropylene) is a lightweight thermoplastic polymer. The straps are flexible, often textured for grip, come in many colours and widths, and are easily printed for branding. PP’s chemistry gives it good stretch and shock absorption for light loads.

2. PET (polyethylene terephthalate) is a polyester material (the same polymer family as many beverage bottles) engineered for higher rigidity and tensile strength. PET straps are manufactured to tighter tolerances, giving consistent cross-sections and predictable performance for heavier applications.

Takeaway: For light, flexible, printable strapping, choose PP; for engineered, high-strength performance, choose PET.

2. Strength & Durability

1. PP offers adequate strength for carton closing, bundling, and light palletizing. It stretches more before breaking, which can be helpful on irregular or fragile loads, but its maximum breaking force is lower than PET.

2. PET delivers higher tensile strength for the same strap profile and is far more durable under sustained load and rough handling. It’s the preferred choice for heavy pallets, construction materials, and dense cargo.

Takeaway: PET is the stronger, more durable option for heavy and demanding loads; PP is fine for light-to-medium duty.

3. Tension Retention & Elongation

1. PP has higher elongation and is more likely to relax over time under constant tension. That makes it forgiving at application but less reliable for long-term hold—straps may need re-tensioning during long transit or storage.

2. PET exhibits low elongation and excellent tension retention; once properly tensioned, PET holds its grip for extended periods and through temperature changes, reducing the need for re-strapping.

Takeaway: If long-term tension retention matters, PET outperforms PP.

4. Flexibility, Handling & Safety

1. PP is noticeably more flexible and easier to apply by hand. It’s user-friendly for manual operators and small packing stations, and it’s less likely to kink or crack during hand use.

2. PET is stiffer and less forgiving for manual wrapping, but this rigidity helps with consistent automated application and creates a firmer load. PET is also safer to handle than steel alternatives.

Takeaway: For manual, low-volume work pick PP; for mechanised, high-volume lines pick PET.

5. Cost & Total Cost of Ownership

1. PP has a lower upfront cost per roll and is economical for high-volume, low-value goods. Short-term jobs and lightweight products often realise the best unit economics with PP.

2. PET costs more per roll but can lower total costs by reducing product damage, rework, and the number of straps required on heavy loads. For heavy/long-life shipments, PET often delivers better lifecycle value.

Takeaway: PP wins on purchase price; PET often wins on total cost of ownership for heavy or long-term applications.

6. Environmental & Recycling Considerations

1. PP is recyclable in principle, but collection and recycling pathways for loose strapping vary by region. Its low weight reduces material waste, but actual recyclability depends on local infrastructure.

2. PET benefits from a more established recycling stream (and rPET supply), and many PET straps can be recycled into new products. This makes PET the more attractive choice for sustainability-minded operations where recycling is available.

Takeaway: Where recycling infrastructure exists, PET usually offers the stronger sustainability case; PP can still be recycled but is more dependent on local systems.

7. Automation & Tool Compatibility

1. PP works well with hand tools, semi-automatic machines, and many low-tension systems. Its flexibility makes it forgiving on manual lines and smaller packing operations.

2. PET is designed to shine in automated, high-tension equipment and battery-powered tools. It requires correct tensioning and sealing settings to reach optimum performance but pairs excellently with modern strapping machines.

Takeaway: Choose PP for manual or semi-auto workflows; choose PET if you run automated or high-tension equipment.

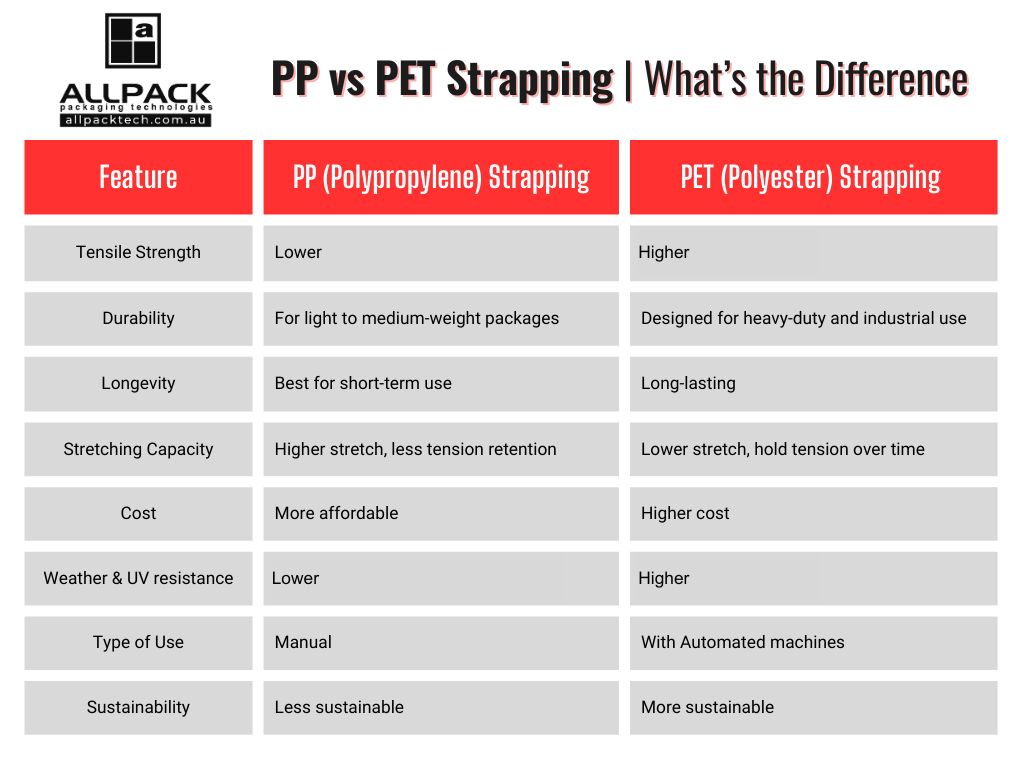

Quick Comparison Between PP and PET Strapping Material

PP and PET strapping each play a vital role in packaging. PP (polypropylene) is affordable, flexible and ideal for light-to-medium loads and manual use. PET (polyethylene terephthalate) is stronger, low-stretch, and better suited to heavy loads, long-term storage, and automated lines.

Use the infographic below for a fast visual snapshot, then read the simple checklist to decide which is right for you.

With the material and differences understood, it’s easier to match each strap to real applications. Below are typical industry uses for both PP and PET.

PP vs. PET Straps Applications/Uses

PP Strapping Applications: Where You Can Use PP Straps?

PP strapping is ideal for industries that handle with lightweight goods. It is used to secure items like timber, pipes, sealing cartons and paper.

It is commonly used in sectors like:

- Food and beverage: Packaging small to medium cartons of food products in boxes, trays, or containers.

- Retail: Securing boxed items and consumer goods.

- Textile: Bundling lightweight fabrics or clothing.

- Pharmaceutical and Healthcare: For packaging pharmacy supplies and lightweight medical equipment.

- Electronics and Appliances: Wrapping small electronic devices & accessories.

PET Strapping Applications: Where You Can Use PET Straps?

PET strapping is suitable for large and heavy materials packaging. E.g. glass, steel, stone, bricks etc. Mostly it is considered for high-value or fragile goods

Some common applications include:

- Construction and building materials: Securing heavy bricks, tiles, or cement.

- Metal and glass: Strapping metal rods, glass panes, or other dense materials.

- Logistics and international shipping: Securing large pallets for long-distance transportation.

- Industrial packaging: Packaging of heavy equipment, metals, etc.

- Beverage industry: Bundling of heavy-weight beverages & large cans.

- Timber transport: Securing planks, logs, and processed pieces of timber & other type of wood.

- Automotive Parts: Packaging bulky automotive parts like engines, radiators, and tyres.

Which One Should You Choose – PP or PET Strapping?

When deciding between PP vs. PET strapping. Consider the weight of your products and the demands of your packaging process.

If you deal with light to medium loads or carton bundling, PP strapping is right for you. But for heavy loads, long-term storage, or outdoor transit, you should choose PET strapping.

Final Takeaway:

- PP = cheap, flexible, forgiving (good for cartons and retail bundles).

- PET = strong, low-stretch, long-lasting (good for heavy, outdoor or long-stored loads).

Looking to Buy PET Strapping Online?

Find PP, PET & Every Type of Strapping Material at Allpack Packaging Technologies

We offer both PP and PET strapping for your business’s packaging needs. Our high-quality products guarantee the secure packaging of every good. From easy-to-use rolls to automated strapping systems, our collection got you covered.

Since 2000, we have been providing custom-built systems and everyday strapping materials. So, you can improve your packaging quality and protect your products.

Shop PP and PET Straps Online Now