If your business relies on fast & secure packaging. A heat sealer can be the game changer for it. These machines seal everything from small plastic bags to industrial bundles. And protects your products from moisture & other damages.

But to get all these benefits. You have to choose the heat sealer designed exactly for your manufacture quantity and product type.

To make it easier for you, we will provide you the insights of its working. Walk you through all the variants. And guide you in selecting the one that suits your business needs.

At All Pack Tech, we are providing Australian businesses with top-quality packaging equipment for 20 years. Our heat sealers can streamline your workflow, increase productivity and reduce the wastage.

Let’s find out everything you need to know about heat sealers.

What is Heat Sealing?

Heat sealing is the method used in packaging which joins two layers of material, usually thermoplastic. It uses a stable, heat-sensitive, and non-contaminating adhesive material. Applies heat and pressure to adhere the layers of it. And results in a waterproof and airtight sealing of the product.

Heat sealer machine uses this technique to provide secure and temperature-resistant packaging. They are popular in various industries like food, medical supplies, and electronics. So, the sensitive products can be kept fresh, clean, and protected from environmental factors.

Let’s find out the principle of their working.

How Do Heat Sealer Machines Work?

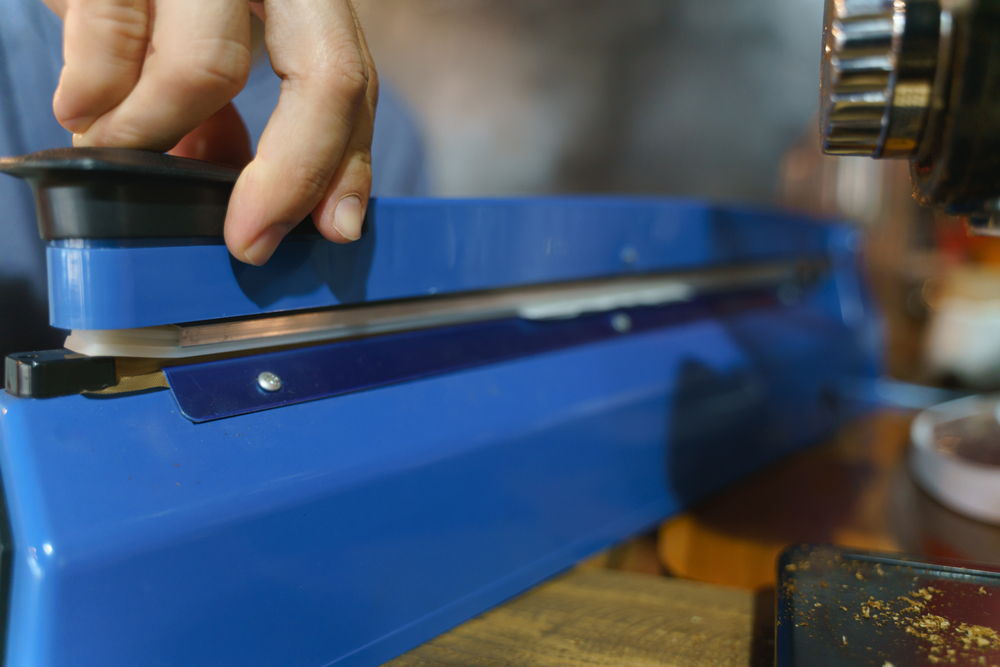

Heat sealer machines operate by using an electric current. Which heats and seals the thermoplastic layers to form a unit. It consists of a heating source, sealing bar, timer, and pressure system.

Heat source is typically an electrically heated bar or pulse. When the heated sealing bar is pushed down and come into contact with packaging material. It melts the surface layer of the material to make it flexible and adhesive.

The two layers are pressed together. And as the heat dissipates, they fuse. Forming a tight and durable seal. Timer controls how long heat and pressure are applied. And pressure system decides the force of pressing. So, a consistent seal is formed every time.

Different heat sealers use varying amounts of heat and pressure. Depending on the material and the type of seal needed. They are the need of every business dealing with mass production. Let’s see why.

Why Heat Sealers are Needed for Packaging?

Investing in heat sealing machines brings several key advantages:

| Advantage | Details |

| Product Protection | The airtight leak-proof seal protects from moisture, dust, and contaminants. (useful for food and pharmaceuticals) |

| Efficient Production | Heat sealers speed up packaging and assist the high-volume production. |

| Extended Shelf Life | Airtight seals preserve the freshness of food & other consumables. So, long-term storage becomes easy. |

| Cost Management | Heat sealers help companies financially by increasing production, reducing labour, and cutting packaging waste. |

| Energy Efficiency | Lower waste means fewer pollutants and less resource consumption. This makes heat sealers an eco-friendly choice. |

| Versatile Application | Customisable settings (temperature, pressure, material, time) make heat sealers adaptable for various products and industries. |

Let’s find out the different types of heat sealers.

Types of Heat Sealers & Sealing Machines

Heat sealers come in a variety of types. Each suited for specific applications and packaging requirements.

Following are some important variants and their detailed uses.

1. Impulse Heat Sealers

Impulse sealers heat up only when the sealing arm is pressed down. Or up to the set sealing time. They’re energy-efficient and used only for sealing thin materials (that don’t need high pressure). E.g. polyethylene and polypropylene.

They are cost effective with less need of power. As the jaws are heated immediately. The brief heating time also reduces the chances of burns.

Impulse sealers are commonly used for sealing small packages or bags, often in retail and food service industries.

You can get a huge variety of impulse bag sealers at All Pack Tech

| Product Name | Benefit |

| Daily Sealing HX Series | Lightweight, single-impulse sealer Built-in fuse for safe use |

| DAILY SEALING LONG HANDLE SERIES | Provides a long sealing length (up to 1000mm) Suitable for heavy-duty applications |

| DAILY SEALING H SERIES PORTABLE | Compact and portable single-impulse sealer Quick heating and reliable seals |

| DAILY SEALING HT SERIES PORTABLE | Double impulse capability (for thicker materials) 400 mm flexibility in sealing |

| Hana NT Series | Available in multiple lengths and seal widths Great for medium-volume needs. |

| Hana XP Series with Cutter Blade | Features a built-in cutter for precise material trimming Suitable for food packaging (clean finish). |

2. Constant Heat Sealers

Constant heat sealers maintain a steady heat level in sealing jaws. So, they can easily mould and seal the thicker materials. They offer more controlled temperature for a longer time.

Constant heat sealers are highly effective for poly-coated materials. As they need a continuous, thick and strong seal. E.g. foils and laminates.

They are used in medical and industrial packaging.

3. Foot Pedal Sealers

Foot pedal sealers provide hands-free operation. It is ideal for users handling bulky or heavy packages.

They can be used in small businesses that need flexibility in their packaging processes. As they combine manual control with heat sealing power.

Explore our range of foot sealers at All Pack Tech

| Product Name | Benefits |

| DAILY SEALING F SERIES | Continuous, hands-free operation For small to medium quick packaging tasks |

| HANA NI SERIES | Durable foot pedal sealer with strong pressure Perfect for heavy-duty packaging |

| DAILY SEALING FT SERIES | Features temperature control for precision sealing Suitable for sensitive or heat-specific materials Used in retail and food industries. |

| DAILY SEALING A SERIES ELECTRONIC | Electronic foot sealer with adjustable heat settings For items needing consistent and controlled sealing |

| DAILY SEALING FD SERIES – DIRECT SEALER | Provides direct foot control with high heat output Designed for large, heavy bags and industrial-grade packaging |

4. Band Sealers

Band sealers use a conveyor belt to feed the package through the heating element.

They allow continuous sealing and are used for bags and pouches. Their faster packing makes them useful in high-volume packaging operations. E.g. food and pharmaceutical industries.

They also offer accessories like alphanumerical embossing. Plus, you can set heat levels via temperature controls. And you can change the size of conveyor belts.

All Pack Tech offers you a range of band sealing machines & plastic bag sealers in Perth

| Product Name | Benefits |

| DRC300 Double Roll Bag Closer | Seals multi-wall, flush-cut paper bag (<50 pounds) Production rate of 75 ft. per minute. A double roll for more durability (Make 2 folds of seal) |

| PBC6000 Pinch Bag Closer | Provide a firm and consistent seal on pinch-style bags Seals powdered or granular products (spill-proof) Used for pet food, pesticides and fertilizers |

| PILS300/330 Pinch Inner Liner Sealer | Constant sealing (seals inner liner, then folds and seals the top of pre-glued pinch bag) Integrated in semi or fully-automated bagging applications Beneficial for food products needing extra freshness and security. |

| SAXON SH1000 | Continuous band sealer Seals the heat-sealable pillow-style plastic bags Great for industrial use (chemical or food material) |

| SAXON SB2000 | Durable design and stainless-steel finish Perfect for medium- to large-scale sealing operations Enhanced cooling capability |

| SAXON SB4000 | Heavy-duty, high-speed band sealer Handles large volumes efficiently |

| EX720/EX720P Vertical Band Sealer | Vertical design is optimal for sealing liquids Offers reliable and airtight sealing |

| EX700P Horizontal Band Sealer | Horizontal setup suited for solid products Suitable for high-speed applications Easy-to-operate controls |

| EX1000 Large Format Vertical Band Sealer | Designed for large or heavy packages Consistent, high-quality seals on bulky items |

5. Automatic Heat Sealers

Automatic heat sealers allow continuous sealing of thermoplastic films. The control settings are programmed at the beginning. And then consistent seals are formed automatically.

A Constant Automatic Heat Sealer is used for:

- Poly cello films

- Humidity-proof cellophane film

- Aluminium foil coated bag

6. Vacuum Sealers

They remove air from the packaging before sealing. And provide a barrier against oxygen. So, it is used in products like food and sensitive electronics.

Vacuum addition extends the product’s shelf life and keeps the freshness intact.

e.g. EX720/EX720P Horizontal Band Sealer offers a vacuum sealing facility.

You have to choose from these types according to the demands of your business.

How to Choose the Right Heat Sealer for Your Business

Choice of heat sealer depends on your specific packaging needs. And the nature of the products you’re sealing. Here are a few things to keep in mind.

- Material Type

Choose a sealer that can handle the material you’re sealing.

For example, thin plastics work well with impulse bag sealers. While thicker laminates require constant heat sealers.

- Volume Requirements

Production rate of your business decides the type of heat sealer you should choose.

E.g. Lower-volume needs can be met with impulse or foot pedal sealers. But for high-volume operations, band sealers or automated systems are needed.

- Seal Strength

Consider the amount of strength needed for safety of your products.

E.g. Airtight or tamper-evident seal is needed for food or sensitive goods. Vacuum sealers are ideal for these requirements.

- Machine Durability

Always use high-quality materials and trustworthy sources.

A durable machine is required especially for frequent use or heavy-duty tasks.

- Ease of Use

Look for user-friendly controls and easy maintenance products. That can easily fit your operational flow.

e.g. automated band sealers can be more efficient in a fast-paced environment.

Want to Buy Heat Sealer Machines Online?

Choose All Pack Tech for Heat Sealers & Sealing Machines

All Pack Tech is the trusted heat sealers supplier in Australia since 2000. We are here to provide you the reliable packaging machinery that supports your operational goals.

Our products are crafted with durability and efficiency in mind. Offering reliable solutions for businesses of all sizes.

Whether you need a portable plastic bag sealer in Perth or a high-capacity band sealer. We can provide you the right type of tools & automotive machinery. To seal and package your products with utmost protection.