Avoid Damaged Deliveries: Master the Art of Pallet Wrapping

Ever watched a wrapped pallet come undone mid-transit? Or worse, arrive crushed and damaged? If yes, then you know how critical proper pallet wrapping is.

It doesn’t just hold the boxes together, but protect your products & maintain your brand reputation. Yet, many businesses still rely on outdated methods and face serious consequences.

At Allpack Packaging Technologies, we know that efficiency starts with dependable packaging. Since 2000, we’ve been helping Australian manufacturers and distributors wrap smarter using reliable pallet wrappers and packaging systems.

Let’s teach you a thing or two about pallet wrapping & some pro techniques for it.

Why Proper Pallet Wrapping is Important?

A correctly wrapped pallet does more than just hold products in place.

It protects your goods from shifting, falling, or being crushed during transport. So, there’s a reduced risk of contamination from dust and moisture. Hence, your shipment arrives at its destination in the same condition it left your facility.

Here’s what proper pallet wrapping can do:

- Improve load stability by securing the items tightly to the pallet.

- Protect from external elements such as moisture, dirt, or tampering.

- Minimise damage claims and returns, which helps your bottom line.

- Streamline warehouse handling with safer & easier-to-move loads.

And when your pallet looks neat and secure, it reflects positively on your business.

Also Read: Quality Stretch Films & Pallet Wrap | Top 9 Benefits to Know

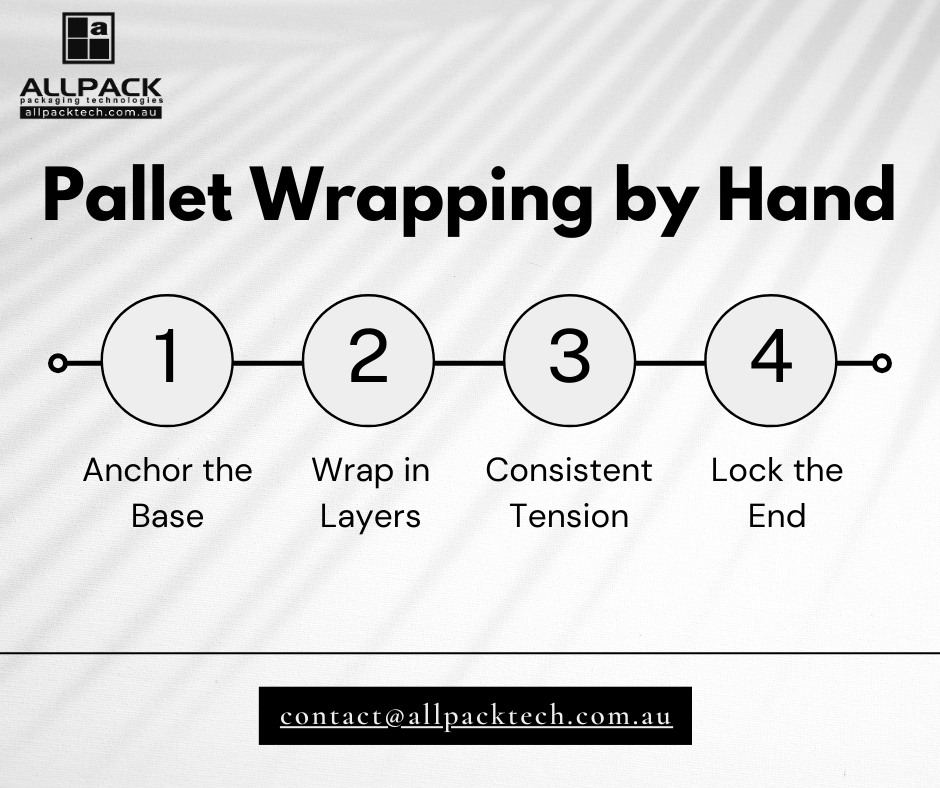

Pallet Wrapping by Hand: Proper Technique

Manual wrapping is still common in many small to mid-sized operations. It doesn’t offer the speed or consistency of a pallet wrapping machine. But can still produce safe, stable pallets if done correctly.

1. Anchor the Base

Always start with securing the plastic wrap at the bottom of the pallet. Tuck the film into the pallet slats or tie it to a corner. Then begin wrapping around the bottom layer of the goods and the pallet. It will:

- Prevents the load from sliding off during movement.

- Ties the goods directly to the pallet frame.

Do at least two or three revolutions to create a solid base connection.

2. Wrap in Layers

Gradually work your way up the load by overlapping each layer of wrap by about 50%. Keep in mind to:

- Wrap in a spiral pattern & keep each new layer tightly linked to the last.

- Apply light but consistent tension as you pull.

- Don’t leave gaps between layers, as these weaken the structure.

- Use more passes for irregular or heavy loads.

It will build a web-like structure that helps the wrap hold firm without tearing.

3. Lock the End

Once you reach the top, wrap over the upper edge to anchor the contents. Then reverse the direction and wrap downward to reinforce the structure. Tie off or tuck the end securely into the wrap layers.

The goal is to create a cocoon that keeps every piece in place, even when the pallet is tilted, jolted, or bumped.

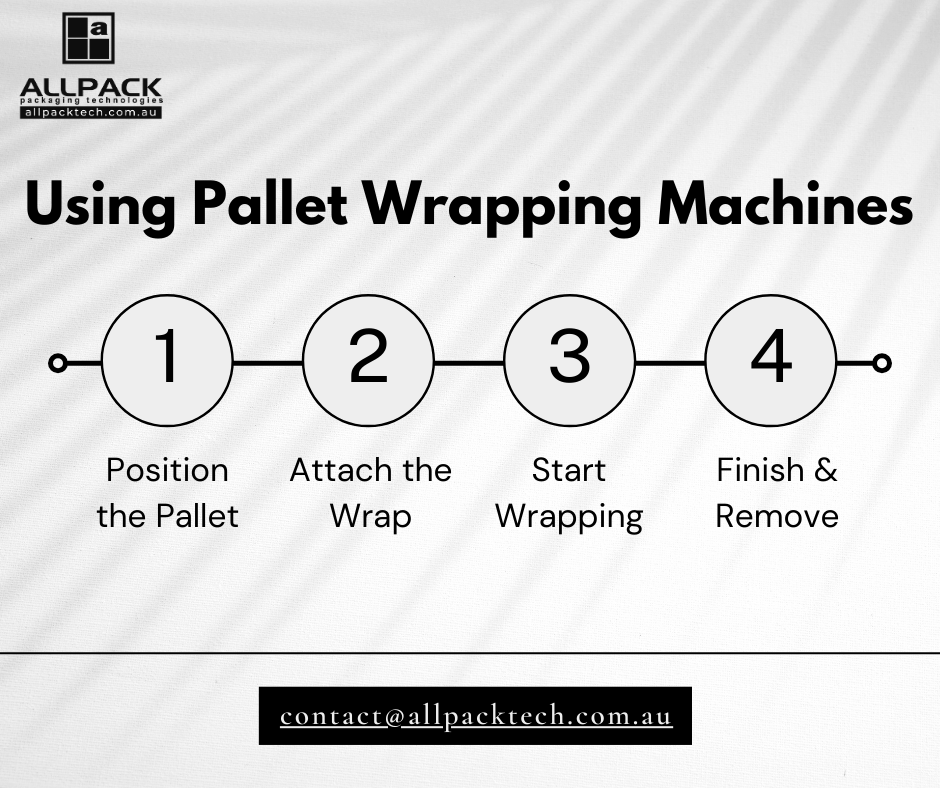

Pallet Wrapping with a Machine

A pallet wrapping machine is a smart investment if you handle large volumes or need consistent quality. It reduces human error, saves time, and helps reduce film waste. Because machine controls the film tension and coverage automatically.

1. Position the Pallet

Make sure your load is correctly aligned on the machine’s turntable or within the wrapping zone. The pallet should be centred and stable, with no overhanging goods. Poor positioning can lead to uneven wrapping and unstable loads.

2. Attach the Wrap

Pull out the stretch film and secure it to the corner or bottom of the pallet. You can also place it in the machine’s clamp (depending on the model). This initial attachment allows the film to wind smoothly and evenly.

Common types of pallet wrappers used are:

- Turntable machines for lighter, evenly loaded pallets.

- Rotating arm machines for very heavy or unstable loads.

Choose quality wrappers for consistent layers.

3. Start Wrapping

Set the number of revolutions, tension level, and height of wrap depending on the load. Machine will wrap with uniform film coverage and right amount of stretch. Hence, there will be:

- Controlled tension to prevent tears and sagging.

- Faster and more efficient process than manual labour.

- Reduced film usage through precise wrapping.

Advanced models can adjust wrap zones for delicate or irregular loads.

4. Finish and Remove

When the wrapping cycle is complete, machine cuts the film and seals the end. This process can be manual or automatic depending upon the model of pallet wrapper. Carefully inspect the wrapped pallet to make sure it’s secure and clean-cut.

Pro tip: Make sure the pallet is not loose or wobbly. Apply a few extra rotations at top and base to secure it properly.

Common Pallet Wrapping Mistakes to Avoid

Even small errors in the process can lead to significant issues during shipping. Be aware of these common missteps.

Common Mistake | Why It’s a Problem |

Loose film tension | A wrap without proper stretch won’t hold the load in place. |

Skipping the base or top layers | Leaves the goods vulnerable to shifting or exposure. |

Too few wrap revolutions | Not enough layers can compromise stability. |

Uneven load stacking | If boxes are not stacked evenly, wrapping won’t compensate. |

Wrong type of film | Choose wrap that matches your product weight and shape. |

Training your staff to spot and avoid these issues. So, every wrapped pallet can meet your safety standards. Always buy from quality pallet wrapper suppliers Perth for better quality of the process.

Also Read: 10 Smart Tips to Choose the Best Pallet Wrapper & Save Big

Additional Tips for a Proper Wrapped Pallet

Need some more tips? Read on.

- Use corner guards on fragile loads to prevent the wrap from damaging edges.

- Label clearly on the outside of the wrap or use label holders.

- Keep loads flush with the pallet edge, overhanging items can tear the wrap.

- Use a turntable for heavy loads to reduce strain and increase precision.

- Rotate stock to use older stretch film first, preventing degradation over time.

Implementing these small changes can greatly improve your overall packaging performance.

Sustainable Pallet Wrapping Practices

As environmental awareness grows, businesses are under pressure to reduce plastic waste. So like any other process, your pallet wrapping should also be efficient and eco-friendly.

Some recommended practices in this regard are:

- Switch to recycled or biodegradable films: They are both strong and sustainable.

- Use pre-stretched film: It requires less effort and less material for the same holding force.

- Recycle used stretch wrap: Set up a system to collect, compress, and send wrap to recyclers.

- Monitor usage: Machines use far less wrap than manual methods and also track your film use over time.

- Train staff: Educated staff means fewer mistakes, less waste, and smarter wrapping habits.

It will not only helps the planet, but also lower costs and improve your brand image.

Need Better Packaging Solutions?

Trust Allpack Packaging Technologies

Our packaging solutions can help you wrap faster, safer and smarter.

From pallet wrapping machines to fully custom systems, we’ve supported Aussie businesses since 2000 with gear that performs. Our machines are tough, easy to use and built for the rigours of daily use.

So, if you are starting small or scaling up, we’ll help you find the right system to reduce downtime, minimise waste and keep your supply chain moving.

Contact Us Today to talk about your packaging needs