Types of Stretch Pallet Wrappers: Which One to Buy in 2025?

Every day in warehouses and manufacturing facilities around Australia, workers engage in manual pallet wrapping. Means continuous lifting, bending, twisting, and pulling stretch film around heavy loads.

These repetitive movements cause 36% of all workplace injuries. According to the Bureau of Labor Statistics, there were over 170,000 US work-related back and spinal injuries in a single year, with sky-high amounts of medical expenses.

On top of that, manual methods result in poorly wrapped pallets, that lead to $50-$500 loss per truckload from spoilage, returns, and delays.

Good news is, you can avoid much of this damage, with the solution simpler than you think. Just bring pallet wrapping machines into your warehouse, & save the health of your workers & finance of your business.

That’s precisely why Allpack Packaging Technologies advocates the use of pallet wrappers. We’ve seen firsthand how businesses can enhance sales & protect the well-being of their team with stretch wrappers.

Let’s guide you on how to utilise this technology for your business.

What Is a Pallet Wrapper?

A pallet wrapping machine (also called a stetch wrapper) is an industrial machine to wrap stretch film securely around a palletised load. It automates the once manual task of wrapping with consistent tension and coverage. So, the product is secured & transported easily.

These machines use stretch film in wrapping for pallets. This film or pallet wrap which is highly stretchable plastic that keeps products bound together on a pallet.

So, if you’re wrapping for shipping, storage, or warehouse organisation, and want your products to arrive in excellent condition. Use a pallet wrapping machine to streamline the process and reduce material waste.

Why Use a Stretch Wrapper for Pallet Wrapping?

A stretch pallet wrapper gives you even & secure wrapping in a fraction of the time compared to manual methods. So, you can benefit with:

Improved load stability | Less risk of shifting or falling during transport |

Reduced film waste | Controlled film application means no more over-wrapping |

Better presentation | Clean, neat wraps for improved customer satisfaction |

Higher throughput | Wrap more pallets per hour without fatigue |

No matter your industry is food, beverage, manufacturing, or distribution. An electric pallet wrapper can dramatically optimise your workflow as compared to manual methods.

Hand Wrapping vs. Pallet Wrappers Machine

Hand wrapping can work fine for low-volume operations. But as your business grows, so do your packaging demands. Manual wrapping is time-consuming, inconsistent, and labour-intensive. It also increases the risk of repetitive strain injuries for workers.

In contrast, a pallet wrappers machine offers:

- Faster wrapping times

- Consistent tension control for better load security

- Less film usage, saving costs

- Reduced injury risk

- Increased productivity

We recommend to shift from hand wrapping to a pallet wrapping machine if you exceed 10–15 pallets/day. It’s a long-term investment that pays off in efficiency & savings.

Also Read: Avoid Damaged Deliveries: Master the Art of Pallet Wrapping

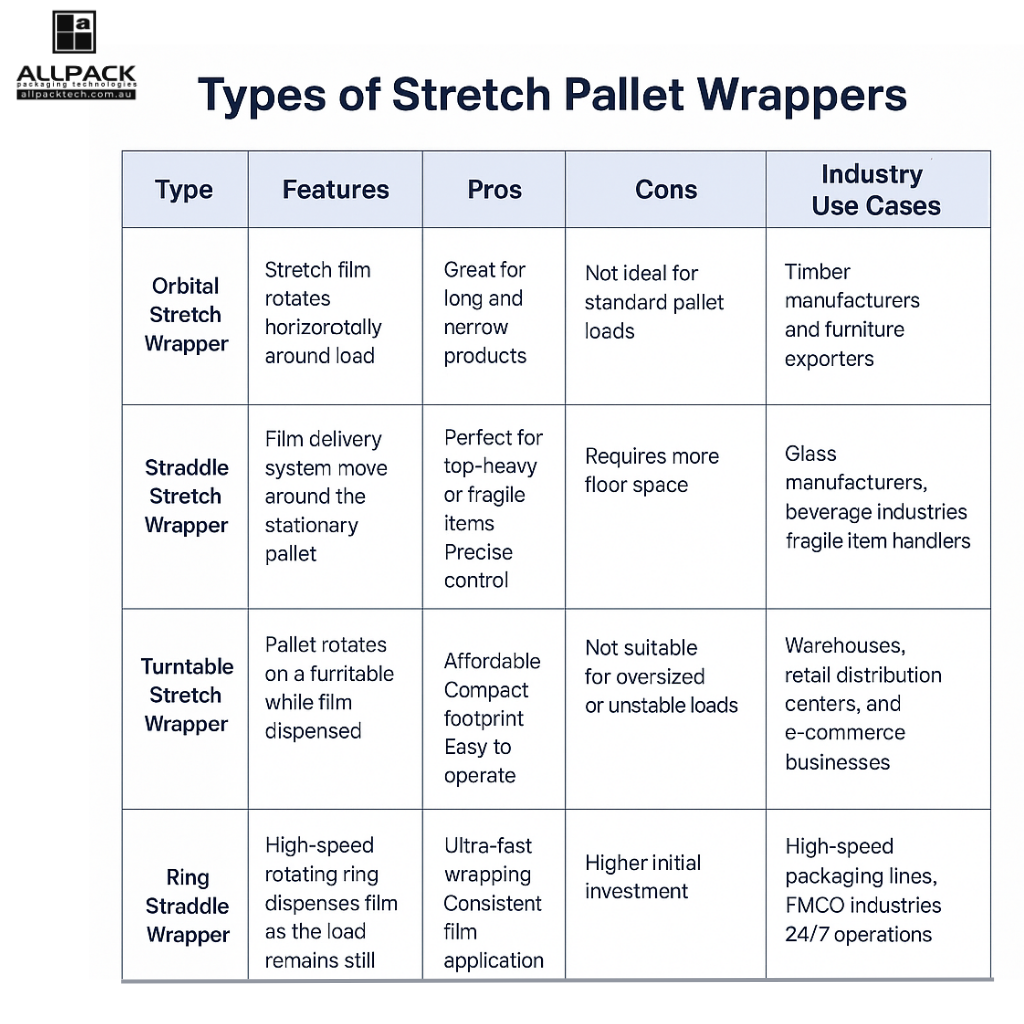

Types of Stretch Pallet Wrappers

Let’s explore the main types of stretch pallet wrappers, with their features, pros, cons, and use cases. Each model suits different operational needs. So, choosing the right one depends on your volume, load type, and available space.

1. Turntable Stretch Wrapper

A turntable stretch wrapper is one of the most common types. It has a rotating turntable with pallet on it, while the film wraps the stretch film around the load. The pallet is wrapped from top to bottom & then in reverse for maximum coverage.

Best For: Low to medium-volume operations with stable & uniform loads.

Pros:

- Compact footprint

- Easy to operate

- Affordable

Cons:

- Can’t be used for very heavy or unstable loads

Use Case: Warehouses, small factories, and retail distribution centres.

2. Orbital Stretch Wrapper

Orbital or ring wrapper moves the pallet using a conveyer machine. This horizontally spinning ring apply stretch film over and under the pallet. So, unstable & unique shaped loads like doors, pipes, carpet rolls or furniture can get wrapped easily.

Best For: Non-palletised, elongated loads or oddly shaped items.

Pros:

- Suit the long loads

- Custom wrap profiles

- Space-efficient models available

Cons:

- Not suitable for standard palletised loads

- Requires operator input

Use Case: Timber, aluminium, furniture, and construction industries.

3. Straddle Stretch Wrapper

This type of wrapper keeps the pallet static and wrapping is done with film rotation. As there is a rotating arm that circles the film around pallet. It is perfect for wrapping unstable, fragile or heavy loads without any risk.

Best For: Tall, heavy, or unstable loads that shouldn’t spin.

Pros:

- Wraps without spinning the load

- Suitable for fragile or unstable goods

Cons:

- Larger footprint than turntable models

- More expensive

Use Case: Bottling plants, fragile goods, or delicate stacked loads.

4. Ring Straddle Wrapper

It is a high-speed automatic pallet wrapper that can wrap around 200 pallets in one hour. Ring straddle wrapper uses a continuous ring motion to wrap products. It’s a fully automated system which is not used commonly, and only built for high-volume production lines.

Best For: High-output businesses needing fast, efficient, automated wrapping.

Pros:

- Extremely fast

- Fully automated

- Consistent wrap every time

Cons:

- Higher initial investment

- Requires technical setup and space

Use Case: Food & beverage production, logistics hubs, and automated warehouses.

Automatic vs. Semi-Automatic Pallet Wrapping Machines: Which One Do You Need?

Choosing between a semi-automatic and an automatic pallet wrapper depends on your business’s daily wrapping needs.

Types of Stretch Wrapper | Working | Suitable for |

Semi-Automatic | Operator initiates and ends the cycle | Operations wrapping 10–50 pallets per day |

Automatic | Conveyor integration for hands-free operation | High-volume operations (100+ pallets/day) |

Read More at: Semi vs. Automatic Stretch Wrapper Machine: Key Differences

We supply both automatic pallet wrappers and semi-automatic machines. Our team can help assess your current operations and give suitable recommendations. So, you can choose suitable option according to volume, budget, and layout of your business.

Pallet Wrapping Machine Price: What to Expect?

Prices for pallet wrapping machines vary based on type, features, and automation level.

Type | Price Range (AUD) |

Turntable Wrapper | $6,000 – $12,000 |

Semi-Auto Arm Wrapper | $10,000 – $20,000 |

Automatic Arm Wrapper | $25,000 – $60,000 |

Ring Straddle Wrapper | $70,000+ |

If you shop at Allpack Packaging Technologies, we believe in offering value with quality. Our machines are built to last, using top-grade materials and the latest technology. Hence, you’ll get long-term performance with minimal downtime.

We have pallet wrappers for sale at competitive prices across Australia and can also custom-build the systems to match your exact needs.

How to Choose the Best Pallet Wrapper for Your Business?

Well, it all depends on the needs of your business & types of loads you deal with. Keep these things in mind and you’ll get the best machine. Remember to buy from trusted suppliers because investment in good quality never get wasted.

Here are a few factors you should consider when choosing your pallet wrapper.

- Load Stability: If you deal with fragile or unstable goods, a rotating arm wrapper is better than a turntable.

- Volume: High-output operations benefit most from automatic pallet wrappers.

- Space: Turntable models are compact, while straddle and ring types need more room.

- Budget: Balance your budget with the long-term savings of reduced film use and labour.

- Film Type: Match the machine specs with your stretch film’s thickness and size.

For More Details: Choosing the Best Pallet Wrapper: Expert Buyer’s Guide 2025

If you are still confused, our team can guide you through these decisions. We’ll assess your production line and offer the best solutions off-the-shelf or custom-built.

Why Choose Allpack Packaging Technologies?

Since 2000, the businesses across Australia choose & trust us for every type of packaging equipment supply across. Because we offer:

- High-performance pallet wrapping machines

- Custom-built packaging systems

- Expert support & local service

- Reliable after-sales assistance

- Competitive pricing

Our commitment to quality means fewer breakdowns, faster operations, and more uptime for your business. When you invest in an electric pallet wrapper from us, you’re choosing efficiency, safety, and long-term performance.

Ready to Upgrade Your Pallet Wrapping?

Upgrade Your Pallet Wrapping with Allpack Packaging Technologies

If you’re looking to improve your packaging line, cut costs, and increase productivity, now is the time to explore our range of pallet wrappers. From semi-automatic turntables to fully automated ring straddle machines, we have the solution for every business size and sector.

Explore Our Pallet Wrapping Machines

Contact Us Today to Get a Custom Quote

Let’s make your packaging smarter, faster, and stronger together.